In the fast-paced world of manufacturing, the automatic packaging machine stands out as a key innovation. These machines have transformed how products are packaged. According to Dr. Emily Carter, a leading expert in packaging technology, "An automatic packaging machine increases efficiency while minimizing human error." This statement highlights the significance of automation in packaging.

Automatic packaging machines streamline processes. They reduce the need for manual labor and enhance precision. For example, these machines can pack thousands of items per hour, making them ideal for mass production. However, the transition to automation isn't always smooth. Some companies struggle to adapt their workflows. This can lead to temporary slowdowns during implementation.

The evolution of the automatic packaging machine presents both opportunities and challenges. While efficiency is gained, the human touch is sometimes lost. It's essential to evaluate how automation affects the workforce. Balancing technology with effective human interaction is crucial. Hence, understanding the full impact of these machines is vital for any industry looking to innovate responsibly.

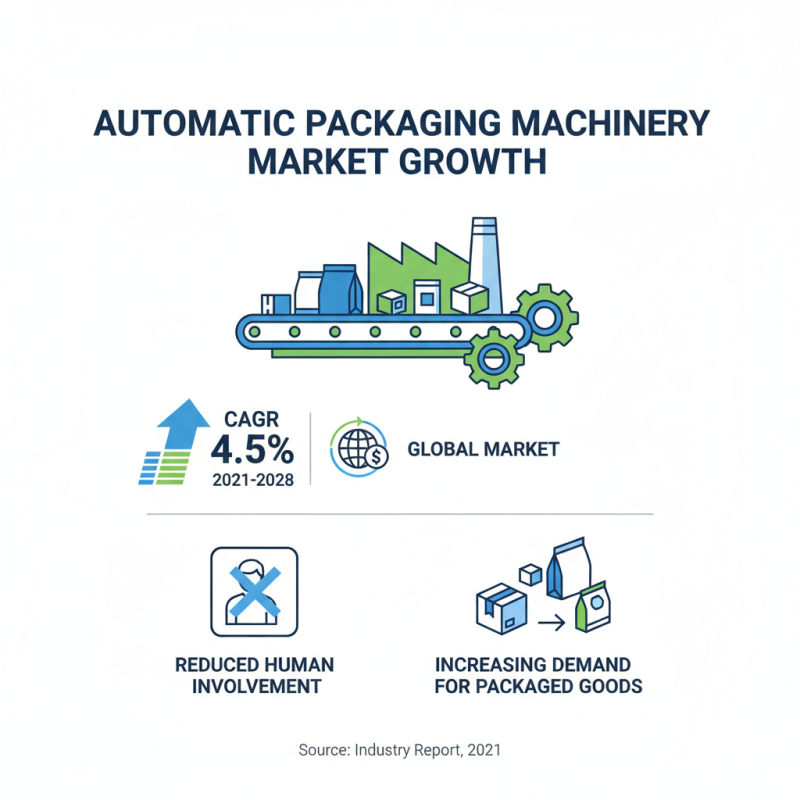

An automatic packaging machine is a device designed to package products efficiently and reliably. These machines can handle a variety of materials, ranging from bags to boxes. They significantly reduce human involvement in the packaging process. According to a recent industry report, the global automatic packaging machinery market is expected to grow at a CAGR of 4.5% from 2021 to 2028. This growth is driven by the increasing demand for packaged goods.

Key features of these machines include versatility, speed, and precision. Versatility allows them to accommodate different product sizes and shapes. Speed is a crucial factor, as modern automatic machines can package up to 300 units per minute. Precision ensures that each package is sealed and labeled correctly, which is vital for maintaining product integrity. However, integrating such machinery requires a significant upfront investment, which can be a barrier for smaller businesses.

Moreover, while automatic packaging machines enhance productivity, they also pose challenges. Maintenance can be a complex and costly process. Additionally, the reliance on automation may lead to skill gaps among the workforce. A study indicated that 23% of companies reported difficulties in finding skilled technicians to operate and maintain these systems. As the industry evolves, balancing automation and human expertise remains a critical consideration.

Automatic packaging machines are essential in modern manufacturing. They streamline the packaging process, boosting efficiency and consistency. Various types serve different industries and products. These machines can cater to food items, pharmaceuticals, electronics, and more.

One common type is the flow wrapper. It wraps products in flexible film. This machine works quickly, maintaining high speed without sacrificing quality. Another type is the vertical form fill seal machine. It forms bags from a flat roll of film, fills them with product, and seals them. This method is popular for snacks and powders. The accuracy and efficiency of these machines help reduce waste and ensure product safety.

However, challenges exist. Operators must ensure machines are calibrated correctly. Misalignments can lead to packaging errors, wasting materials. Regular maintenance is crucial to prevent breakdowns. Neglecting this can slow production and increase costs. Understanding these machines and their needs is vital for smooth operations.

Automatic packaging machines play a vital role in modern manufacturing and logistics. These machines streamline the packaging process, enhancing efficiency and reducing labor costs. According to a recent industry report, the global automatic packaging machinery market is projected to grow at a CAGR of 4.8% from 2022 to 2030. This highlights their increasing importance across various sectors.

The principles of operation for automatic packaging machines are based on automation and precision. Sensors detect products on the conveyor belt, triggering the packaging sequences. Components like fillers, sealers, and labelers work in harmony to prepare each item for distribution. However, while these machines improve speed, they can also present challenges. Misalignment can occur, causing jams or faulty packages. Regular maintenance is crucial to mitigate these issues, though it is often overlooked.

Training staff to operate and troubleshoot automatic packaging machines is essential. Despite technological advancements, human oversight remains important. Statistics reveal that human error still accounts for up to 30% of operational failures in automated systems. Balancing technology and human expertise can create a more efficient, reliable packaging system.

Automatic packaging machines play a crucial role in various industries. They increase efficiency and reduce labor costs. These machines are widely used in food, pharmaceuticals, electronics, and cosmetics. Each industry has unique requirements, and the packaging machine adapts accordingly.

For example, in the food industry, these machines ensure that products remain fresh and safe for consumption. They work quickly, packing items like snacks or frozen meals at high speeds. In pharmaceuticals, accuracy is vital. Machines must package pills and syringes precisely to meet strict regulations.

Tips: Always consider the specific needs of your product. Not all machines fit every application. It's crucial to evaluate the materials and sizes for compatibility. Regular maintenance is essential for optimal performance. Neglecting this can lead to costly downtime.

The electronics sector also benefits greatly. Packaging sensitive components requires careful handling. These machines can create protective layers while speeding up the process. In cosmetics, visual appeal is key. Machines must create eye-catching packaging to attract consumers.

Tips: Invest in a machine that fits your production scale. Large production does not always require the most complex technology. Sometimes, simplicity leads to efficiency. Always stay updated on technology trends. Improvements can enhance speed and reduce waste.

The packaging machinery sector is witnessing significant growth and innovation. Companies are integrating advanced technologies, such as automation and artificial intelligence, into their packaging processes. These technologies streamline operations and enhance efficiency. Manufacturers are now capable of adapting to rapid market changes. This flexibility allows them to meet diverse packaging requirements more effectively.

Sustainability is another driving force behind innovations in packaging machinery. Many businesses are focusing on eco-friendly materials and practices. This shift addresses consumer demand for sustainable options. Packaging that minimizes waste can enhance brand image. However, transitioning to sustainable methods can be challenging and requires careful planning.

While automation improves productivity, it also raises concerns. There may be job displacement as machines take over repetitive tasks. Workers in the industry must adapt to new realities. Training and upskilling become vital to navigate this evolving landscape. Balancing technology with human resources is an ongoing challenge. The future of packaging machinery demands creativity and strategic thinking.

The global packaging machinery market has exhibited consistent growth from 2020 to 2025, driven by increasing demand for automated solutions across industries. This bar chart illustrates the projected market size in billion USD through the specified years, highlighting the trend towards automation and efficiency in packaging solutions.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals