In the rapidly evolving landscape of modern manufacturing, the integration of technology plays a pivotal role in enhancing efficiency and productivity. One of the most significant advancements in this sector is the automatic filling machine, a tool that has revolutionized the way products are processed and packaged. According to Dr. Emily Carter, a leading expert in manufacturing technologies, "The automatic filling machine is not just a piece of equipment; it's a catalyst for transforming operational capabilities."

With its ability to streamline filling processes across various industries, the automatic filling machine offers substantial benefits that include increased speed, accuracy, and reduced labor costs. These machines are engineered to handle a wide range of liquids and semi-liquids, ensuring that businesses can maintain high standards of quality and consistency in their products. The shift towards automated solutions is not merely about keeping up with industry trends; it represents a fundamental change in how manufacturers approach efficiency and competition.

As companies continue to embrace automation, understanding the top benefits of using an automatic filling machine becomes essential. The resulting improvements in production capacity and resource management can significantly impact a business's bottom line, setting a new standard in manufacturing excellence.

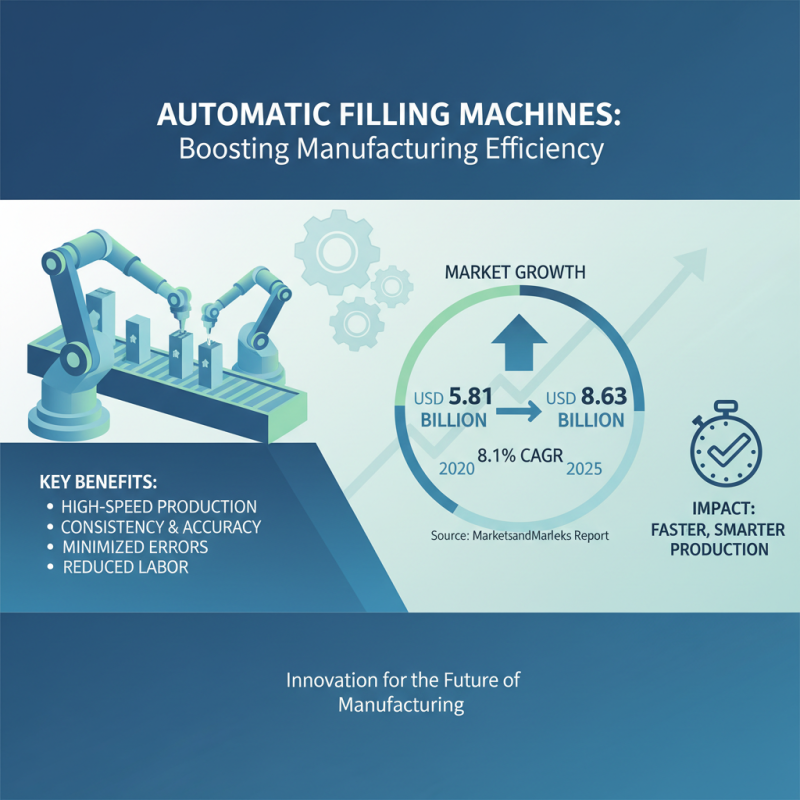

Automatic filling machines have become increasingly crucial in modern manufacturing, particularly due to their significant impact on production efficiency. According to a report by MarketsandMarkets, the automatic filling machine market is expected to grow from USD 5.81 billion in 2020 to USD 8.63 billion by 2025, at a CAGR of 8.1%. This growth is driven by the need for high-speed production, consistency, and accuracy in filling processes. Automatic machines drastically reduce human intervention, minimizing errors and ensuring that products meet the required specifications without the variability often seen in manual filling.

One of the major advantages of automatic filling machines is their ability to streamline production lines. A study from the International Journal of Advanced Manufacturing Technology highlighted that manufacturers utilizing automatic systems achieved a 20-30% increase in output compared to traditional manual methods. This increase is not just due to speed; it also stems from optimized workflows and reduced machine downtime, allowing for a more agile production environment.

**Tips:** When considering the transition to automatic filling systems, assess the scalability of the machines to accommodate future production needs. Additionally, ensure that employees are trained to monitor and maintain these systems effectively, as proper maintenance can further enhance efficiency and prolong equipment lifespan.

In modern manufacturing, the integration of automatic filling machines has led to significant reductions in labor costs. By automating the filling process, manufacturers can minimize the number of staff needed on the production floor. This streamlining of operations allows companies to allocate their workforce more efficiently, focusing on higher-level tasks that require human oversight and creativity rather than repetitive manual labor. As a result, businesses can also reduce training costs associated with hiring and managing personnel for filling duties.

Furthermore, the consistency and speed offered by automatic filling solutions enhance productivity while decreasing the likelihood of human error, which can lead to costly mistakes. With faster cycle times, these machines can complete tasks in a fraction of the time it would take human workers, effectively increasing output without a corresponding rise in labor costs. Additionally, as labor rates continue to rise in many regions, the return on investment for automatic filling machinery becomes more appealing, enabling manufacturers to maintain competitiveness in an ever-evolving market. The shift towards automated processes not only drives down operational costs but also positions companies for future growth and innovation.

| Benefit | Description | Impact on Labor Costs |

|---|---|---|

| Increased Speed | Automatic filling machines can operate at high speeds, significantly increasing production output. | Reduces the number of hours needed for filling processes, lowering labor expenses. |

| Consistency and Precision | Ensures uniform fill levels and reduces wastage through precise control of the filling process. | Decreases the need for manual adjustments and oversight, lowering the need for skilled labor. |

| Reduced Labor Requirements | Automation minimizes human intervention in the filling process, allowing businesses to operate with fewer employees. | Significantly lowers labor costs associated with hiring and training staff. |

| Improved Workplace Safety | Automatic filling machines reduce the risk of workplace injuries that can occur during manual filling. | Lower insurance costs and potential liabilities due to reduced accident rates. |

| Enhanced Scalability | Easily adjustable systems that can scale with production needs without proportional increases in labor. | Optimizes labor allocation, effectively maximizing cost efficiency. |

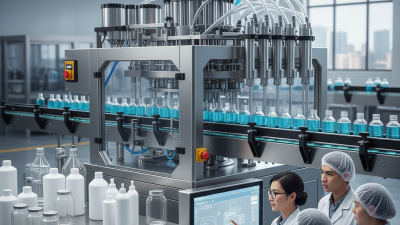

Automatic filling machines have revolutionized modern manufacturing by significantly enhancing product consistency and quality. These machines operate with precision, ensuring that each container is filled uniformly to the specified volume. This level of accuracy is crucial, as it reduces manual errors that can lead to product variation. In industries like food and beverage, pharmaceuticals, and cosmetics, maintaining consistent product quality is essential not only for consumer safety but also for brand reputation.

Moreover, automation eliminates human-induced variability and minimizes the risk of contamination during the filling process. By automatically controlling the filling parameters, manufacturers can apply stringent quality control measures, while data analytics features allow for real-time monitoring. This leads to immediate adjustments when inconsistencies are detected, thereby enhancing the overall reliability of the production output. With automated systems in place, businesses can confidently assure their customers of the highest quality standards with each product batch, ultimately fostering customer loyalty and satisfaction.

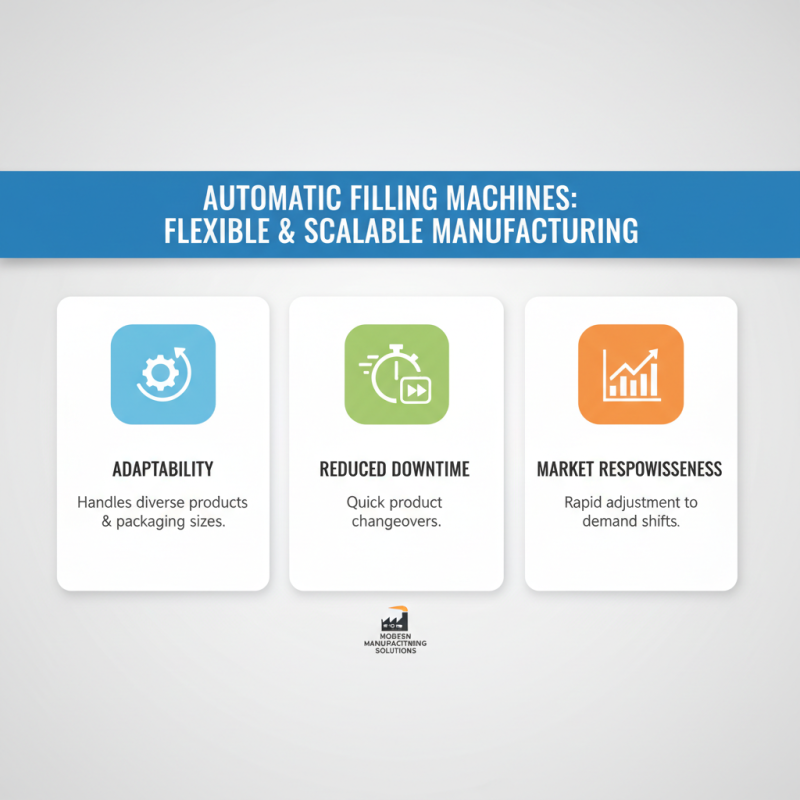

The incorporation of automatic filling machines in modern manufacturing offers significant flexibility and scalability, essential for meeting varying production demands. These machines are designed to handle a wide range of product types and packaging sizes, allowing businesses to switch between different products without extensive downtime. This adaptability is crucial in industries where consumer preferences and market trends can shift rapidly, enabling manufacturers to respond promptly and efficiently to changes in demand.

Moreover, scaling production becomes seamless with the use of automatic filling machines. As a business grows or faces fluctuating orders, these systems can be easily adjusted or expanded to accommodate increased output without the need for a complete overhaul of the production line. With the capability to integrate with other automated processes, manufacturers can optimize their operations, reduce labor costs, and maintain high quality standards all while ensuring that they can scale up production in response to market opportunities. This strategic advantage ultimately helps businesses stay competitive in a dynamic marketplace.

The integration of automatic filling machines in manufacturing not only enhances productivity but also significantly improves safety standards in the workplace. By automating repetitive tasks, these machines minimize the risk of human error, which is often a leading cause of workplace accidents. When employees are no longer required to manually handle potentially hazardous materials or perform monotonous tasks, the likelihood of mishaps decreases, creating a safer environment for everyone involved.

Furthermore, automatic filling machines often come equipped with advanced safety features such as emergency shut-off systems and automated quality checks. These features help to ensure that the filling process is consistent and efficient, reducing the chances of spills or accidents. As a result, companies can maintain a safer work environment while also meeting regulatory compliance requirements, which is crucial in today’s stringent manufacturing landscape.

**Tip:** When implementing automatic filling machines, ensure that employees receive proper training on the equipment's operation and safety protocols. Regular maintenance of machinery is also essential to avoid any potential safety issues. **Tip:** Encourage an open dialogue among employees regarding safety concerns. This can foster a proactive approach to maintaining a safe workplace, allowing workers to feel more at ease and engaged in their roles.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals