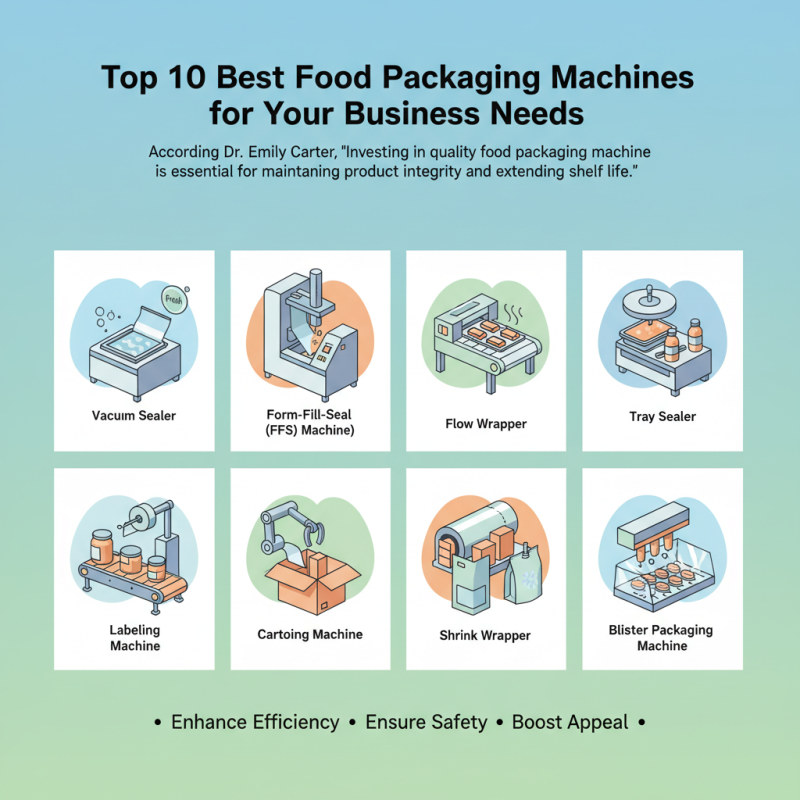

In the ever-evolving landscape of the food industry, the importance of effective food packaging cannot be overstated. According to industry expert Dr. Emily Carter, a leading figure in food technology, “Investing in a quality food packaging machine is essential for maintaining product integrity and extending shelf life.” As businesses strive to enhance their operational efficiency and product appeal, the selection of the right packaging machinery becomes crucial.

Within this guide, we will explore the top 10 best food packaging machines that cater to diverse business needs. From enhancing brand presentation to ensuring food safety, these machines play a pivotal role in optimizing packaging processes. With advancements in technology, modern food packaging machines not only streamline production but also adapt to varying product requirements, enabling businesses to stay competitive in a crowded marketplace. Join us as we delve into the features and benefits of the top contenders, equipping you with the knowledge needed to make informed decisions for your food packaging needs.

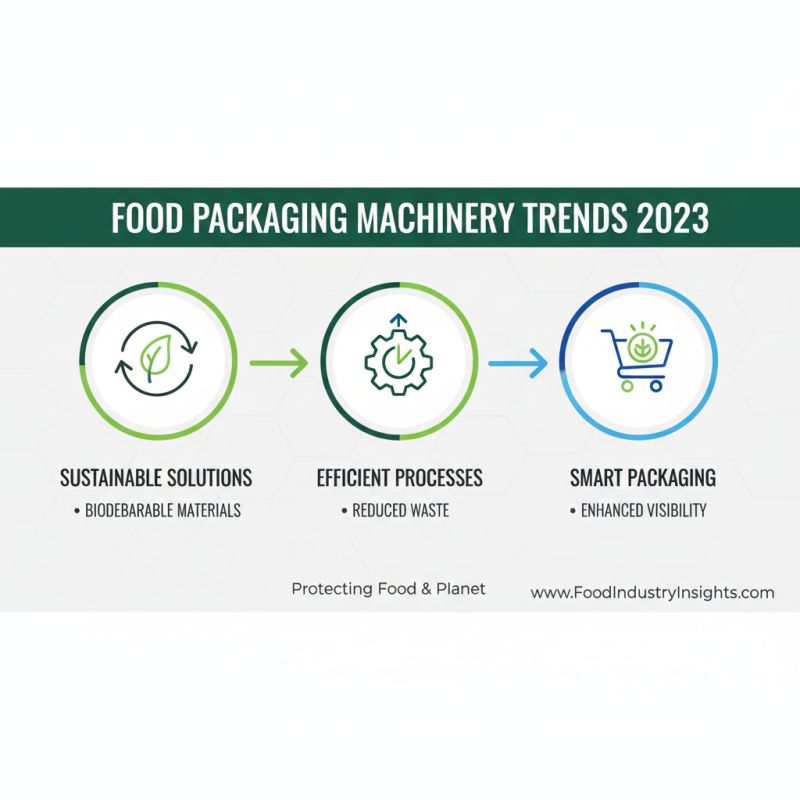

As we move into 2023, businesses in the food industry are witnessing significant advancements in food packaging machinery. The trend is leaning toward more sustainable and efficient packaging solutions that not only protect food quality but also address environmental concerns. Innovations in biodegradable materials and smart packaging technologies are gaining traction, allowing companies to reduce waste and enhance product visibility on shelves.

Businesses should consider implementing automated packaging systems, which are gaining popularity for their ability to streamline production processes. These systems not only increase efficiency but also reduce labor costs, allowing employees to focus on more critical tasks. Additionally, integrating technologies such as artificial intelligence and machine learning into packaging machines can help optimize operations, predict maintenance needs, and minimize downtime.

Tip: When choosing a food packaging machine, assess your business's specific needs and scale. Opt for versatile machines that can handle different packaging types and sizes while ensuring compliance with food safety standards. Another useful tip is to invest in training for your team to maximize the benefits of new technology, enhancing both productivity and product handling.

When selecting food packaging machines, it's vital to consider several key features that can significantly impact your business operations. Firstly, the type of materials the machine can handle is crucial. Different products require different packaging types, such as vacuum sealing, shrink wrapping, or flow wrapping. Understanding the compatibility of the machine with your specific materials ensures not only operational efficiency but also the preservation of food quality.

Another important feature to evaluate is the machine's speed and capacity. Depending on your production requirements, a machine that can keep up with high output demands will be essential. Additionally, consider the ease of operation and maintenance. Machines that offer user-friendly interfaces and are easy to clean will save time and reduce labor costs. Lastly, the level of automation is worth assessing; semi-automatic machines may suit smaller operations, while fully automated systems can greatly enhance efficiency for larger enterprises.

The landscape of food packaging technology has evolved significantly, offering diverse solutions to meet varying business needs. At the forefront are technologies such as vacuum packing, flow packaging, and modified atmosphere packaging (MAP). Vacuum packing removes air from the package, thereby extending shelf life by limiting oxidation. This method is particularly beneficial for perishable goods, as it inhibits the growth of spoilage organisms. Flow packaging, characterized by its efficiency in high-speed operations, is commonly used for products like snacks and frozen foods. It provides durable seals and enhances the product's appeal through clear visibility.

Modified atmosphere packaging further revolutionizes food storage by altering the composition of gases within the package. This technique is particularly advantageous for maintaining freshness in fruits, vegetables, and meat products. By reducing oxygen levels and increasing nitrogen or carbon dioxide, MAP minimizes spoilage and preserves texture and flavor. Each technology has its unique advantages, so businesses must consider factors such as product type, shelf life, and cost efficiency when selecting a packaging solution. The right choice of technology not only improves product longevity but also enhances the overall consumer experience.

When it comes to food packaging, understanding industry standards and regulations is crucial for ensuring safety and compliance. The Food and Drug Administration (FDA) in the United States, along with other international regulatory bodies, establishes guidelines that dictate which materials can be used for food contact, how packaging should be labeled, and the safety measures necessary to protect consumers. According to a report by the Food Packaging Association, over 80% of food safety issues arise from inadequate packaging procedures, underscoring the significance of complying with these regulations to minimize risks.

Implementing efficient food packaging solutions not only helps in meeting regulatory standards but also improves operational efficiency. The packaging industry is projected to grow at a compound annual growth rate (CAGR) of 5.2% until 2026, with sustainability becoming a driving factor. Companies that adopt biodegradable or recyclable materials are better positioned to meet consumer demand for environmentally friendly practices while adhering to regulations that increasingly focus on sustainability.

Tips: When selecting a food packaging machine, ensure it meets the relevant safety certifications and conforms to the necessary regulations in your region. Regular training for staff on compliance procedures is essential to maintain adherence to industry standards. Additionally, consider investing in technology that enables traceability of materials, as this can be crucial in the event of a product recall or safety issue.

Investing in automated food packaging machines presents numerous advantages for businesses in the food industry. One of the primary considerations is the cost-benefit analysis, which underscores the potential savings and enhancements in efficiency. Automated machines typically require a higher upfront investment compared to manual labor; however, the long-term benefits often outweigh these initial costs. Automated systems streamline the packaging process, reducing labor costs significantly and minimizing human error. This not only improves the consistency and quality of packaging but also accelerates production timelines, allowing businesses to meet increasing demand effectively.

Moreover, automated food packaging machines often lead to reduced waste and improved sustainability. By ensuring precision in the amount of packaging materials used and minimizing excess, businesses can operate more efficiently while also being environmentally responsible. Additionally, these machines typically come equipped with advanced technology that ensures hygienic packaging, crucial for food safety. When assessing the return on investment, businesses can factor in both the savings from reduced labor costs and material waste, as well as the potential for greater market competitiveness due to enhanced packaging solutions. Thus, automating food packaging is not merely an investment in machines but a strategic move towards operational excellence and sustainability in the food sector.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals