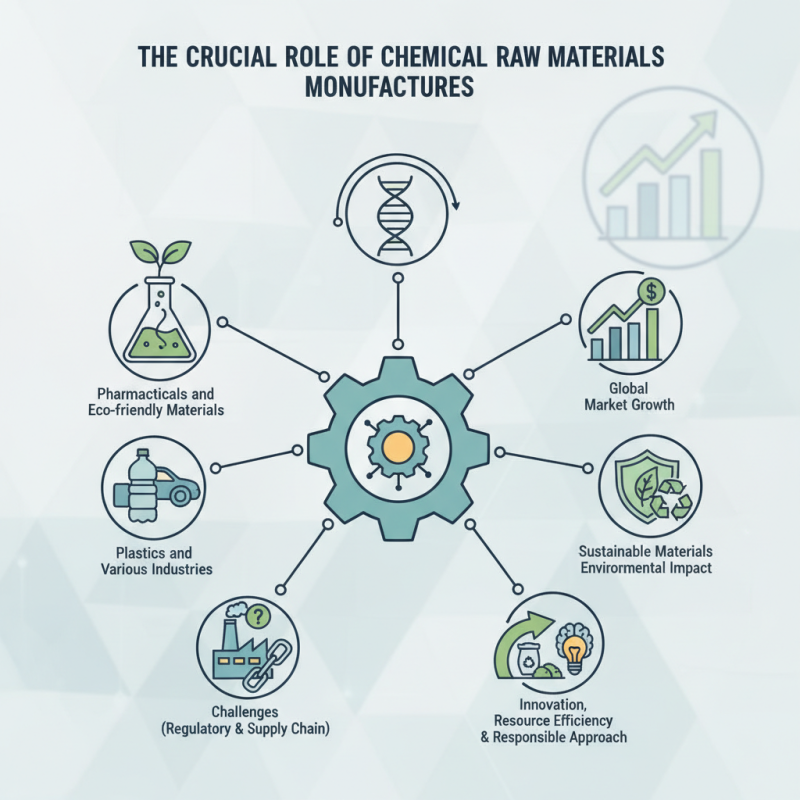

The role of a chemical raw materials manufacturer is crucial in various industries. They supply essential ingredients for products ranging from pharmaceuticals to plastics. According to a recent report from Grand View Research, the global market for chemical raw materials is expected to reach over $5 trillion by 2027, reflecting significant demand across sectors. This aligns with the growing need for innovative and sustainable materials.

chemical raw materials manufacturers not only produce these ingredients but also influence product quality and environmental impact. The demand for eco-friendly materials is rising. However, challenges such as regulatory pressures and supply chain disruptions persist. Manufacturers must adapt swiftly to these changes while maintaining standards.

Despite the importance of their role, some manufacturers face issues related to waste and resource efficiency. A responsible approach is vital for long-term sustainability. Exploring new technologies and practices can enhance their contributions. Ultimately, understanding the role and impact of chemical raw materials manufacturers is essential for fostering a sustainable industrial future.

Chemical raw materials are the foundational substances used in various industries. These materials are essential for producing a wide range of products, from plastics to pharmaceuticals. In 2022, the global chemical raw materials market was valued at approximately $3 trillion. This number reflects their critical role in the economy and everyday life.

The importance of chemical raw materials cannot be overstated. They play a vital role in manufacturing processes across multiple sectors. For instance, the construction industry relies heavily on chemicals like cement and polymers. Moreover, the agricultural sector needs chemical fertilizers for optimal crop yields. However, sourcing these raw materials poses challenges. Sustainability is a pressing concern, with many manufacturers facing scrutiny over environmental impact.

On the other hand, the shift toward greener alternatives shows promise. Increases in bio-based materials and eco-friendly options are notable trends. These shifts strive to balance industrial needs with environmental responsibility. While the need for innovation is clear, not all efforts meet expected standards. The industry must reflect on and improve its practices to ensure a sustainable future.

Chemical raw materials manufacturers play a crucial role in various industries. They produce essential substances that serve as building blocks for numerous products. These manufacturers supply materials like chemicals, polymers, and specialty compounds. Their output supports sectors such as pharmaceuticals, plastics, and agriculture.

One key function is maintaining a consistent quality of raw materials. This ensures that their clients can produce reliable end products. Many manufacturers invest in quality control systems. However, these processes can sometimes be flawed, leading to inconsistencies. The challenge lies in balancing quality with production efficiency.

Another vital aspect is adapting to market demands. Trends change quickly, and manufacturers must respond accordingly. They often need to innovate and develop new materials. This process is not always smooth. Sometimes, the products don’t meet market needs, requiring manufacturers to rethink their strategies. Additionally, environmental regulations can add layers of complexity to their operations. They must find sustainable ways to produce materials while minimizing waste.

Chemical raw materials play a crucial role in various industries. They are the building blocks for countless products. These materials can be categorized into several types, each serving distinct applications. For instance, basic chemicals include substances like acids and alkalis. They are essential in manufacturing plastics, textiles, and pharmaceuticals. According to a report by the Global Chemical Industry, the demand for basic chemicals is projected to grow at a CAGR of 3.1% through 2025.

Another important category includes specialty chemicals. These are used for specific applications, such as coatings, adhesives, and agrochemicals. The specialty chemicals market is expected to reach $1 trillion by 2025, driven by innovations in technology and changing consumer preferences. However, addressing environmental concerns and regulatory challenges remains a crucial hurdle. Manufacturers need to find greener alternatives and improve their sustainability practices.

Moreover, the market for intermediate chemicals is also expanding. These are products that serve as precursors for more complex chemicals. Their applications range from detergents to pharmaceuticals. Despite growing demand, the industry faces pressure to enhance efficiency and reduce waste. Balancing quality, cost, and environmental impact is a continuous challenge for raw materials manufacturers.

Chemical raw materials manufacturers play a crucial role in the production chain. They transform basic materials into substances used in various industries. This process requires precision and attention to detail. Many steps are involved, and each step affects the final product's quality.

The manufacturing process begins with sourcing raw materials. These materials must undergo rigorous testing. Once verified, they move to the next stage: processing. This often involves heating, mixing, and chemical reactions. Each process can change the properties of the materials. Manufacturers must monitor these changes closely.

After processing, the materials are refined for specific applications. This can include further purification or mixing with additives. In this stage, imperfections can arise. It’s essential to evaluate the final product regularly. Even minor flaws can impact performance. Continuous improvement is necessary to meet industry standards.

The chemical raw materials sector faces numerous challenges. Regulatory compliance is a significant hurdle. Manufacturers must navigate complex regulations in different regions. Meeting these standards can strain resources and time. Each shift in legislation can demand immediate adaptations.

Supply chain disruptions also pose risks. Natural disasters or geopolitical tensions can interrupt material flow. Manufacturers must stay agile to respond quickly. They may need alternative suppliers or diversify their sources. Planning for contingencies is essential for stability.

Tips: Regularly review and update compliance frameworks. Implement flexible supply chain strategies. Build strong relationships with diverse suppliers to minimize risks. Consider investing in technology for better transparency and efficiency. In a rapidly evolving market, these steps can help maintain resilience.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals