Choosing the right powder packaging machine can significantly impact efficiency in the manufacturing process. According to a recent report by MarketsandMarkets, the powder packaging industry is projected to grow by 5.1% from 2023 to 2030. This growth highlights the need for robust machinery that meets specific operational demands.

Expert John Smith, a leading authority in the field, states, "Selecting the right powder packaging machine is crucial for optimizing production." His insight underscores the importance of choosing machinery tailored to varying product characteristics. For example, different powders require specific seal types and packaging styles, complicating the selection process.

It's easy to overlook the subtle yet vital differences in machines. Many companies initially favor cost over suitability, which can lead to inefficiencies. Remember, investing in a well-suited powder packaging machine can yield better long-term returns, ensuring the product's quality and safety. Reflecting on these aspects is essential for making an informed choice.

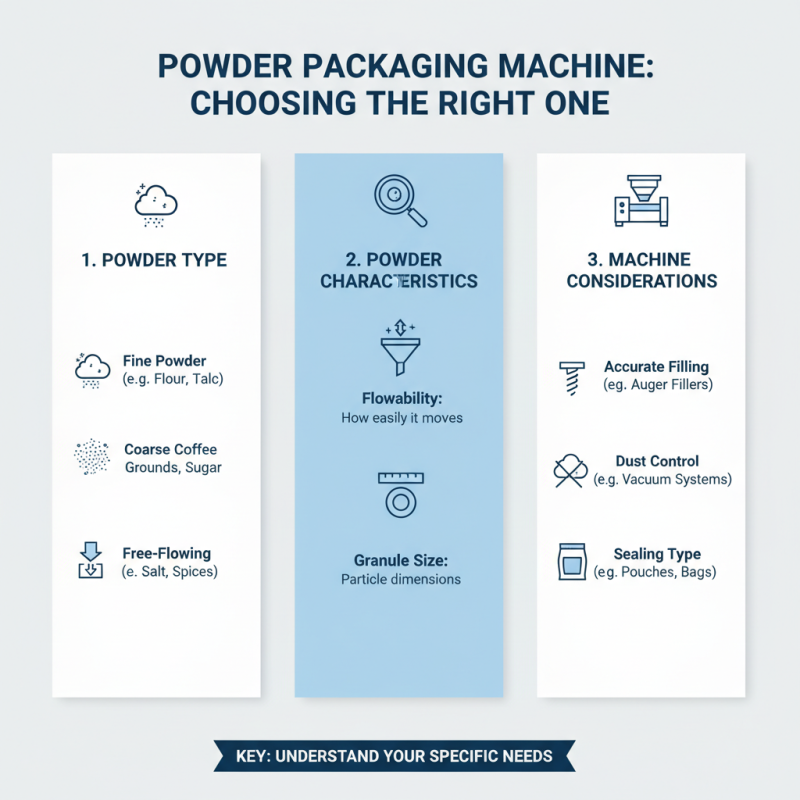

Choosing the right powder packaging machine requires a clear understanding of your specific needs. Different powders have varying characteristics, such as flowability and granule size. Consider the type of powder you will be packaging. Is it fine, coarse, or free-flowing? Each type may require a different approach.

Think about your production goals. How fast do you need to package? This affects not only the speed of the machine but also its size and configuration. Some machines are designed for high-speed operations, while others work best at slower rates. Evaluate how much space you have in your facility. A large machine may not fit well in a compact area.

Consider the materials you will use for packaging. Different materials require different sealing mechanisms. Heat seals might be needed for certain bags, while others may use adhesive. Reflect on the types of closures that suit your product. Lastly, don't forget to factor in maintenance. Machines require upkeep, and some models may be harder to service than others. Think about all these aspects carefully to make a well-informed decision.

Choosing the right powder packaging machine can be challenging. Understanding the types available is crucial. There are several options on the market. Each machine serves a distinct purpose.

One common type is the auger filler. This machine is perfect for fine powders. It measures specific quantities accurately. Another option is the linear filling machine. It is suitable for larger batches. These machines can handle different sizes of bags and containers.

Tips: Consider the material of the powder. Some machines work better with certain materials. Test how easily your powder flows. Remember, not every machine fits all. You may face adjusting issues later.

Make sure to evaluate the speed too. Some machines operate faster than others. But speed shouldn’t compromise accuracy. A fast machine might waste materials if it’s not precise. Take your time and think about your production needs.

When selecting a powder packaging machine, it’s crucial to assess key features that will meet your specific needs. Speed is one of the most critical factors. Machines that operate faster can increase your productivity. However, consider if the speed suits your packaging volume. It might not be effective if the output exceeds your demand.

Accuracy in filling is another essential feature. Look for machines that provide precise measurements to minimize waste. An inconsistent fill can lead to unhappy customers or increased costs. Also, evaluate the machine's adjustable settings. Can it accommodate different powder types? Some powders flow differently and may require unique adjustments.

Finally, think about the machine's ease of use and maintenance. A complex machine might seem appealing, but it can lead to frustration. Look for user-friendly controls. Regular maintenance is essential for longevity, so ensure parts are accessible for cleaning. Remember, convenience can save time and enhance productivity over the long term.

| Feature | Description | Importance |

|---|---|---|

| Machine Type | Choose between vertical, horizontal, or automatic machines based on product type. | High |

| Speed | Assess packaging speed; crucial for high-demand products. | Medium |

| Hopper Capacity | Larger hoppers reduce downtime for refills. | High |

| Accuracy | Ensure precise measurements for product consistency. | High |

| Material Compatibility | Check if the machine can handle your specific powder type. | Medium |

| Safety Features | Look for emergency stops, guards, and alarms for operator safety. | High |

| Ease of Cleaning | Design that facilitates quick cleaning to reduce contamination risks. | Medium |

| Cost | Evaluate total costs, including maintenance and parts replacement. | High |

Choosing the right powder packaging machine greatly impacts efficiency. Research shows that inefficient packaging can lead to a 30% increase in production costs. It’s essential to evaluate various factors to find the best solution.

Consider the operational costs. A machine that is efficient in speed and accuracy can save you money over time. For instance, a study indicated that automation can reduce packaging errors by up to 25%. This improvement translates into significant savings in labor and material waste. Is your current machine meeting these efficiency standards?

Another point to ponder is maintenance costs. Some machines require more upkeep than others. Reports suggest that businesses can save nearly 15% on annual maintenance with the right choice. Think about your long-term goals. Investing in a high-quality machine may seem expensive initially but can provide substantial benefits.

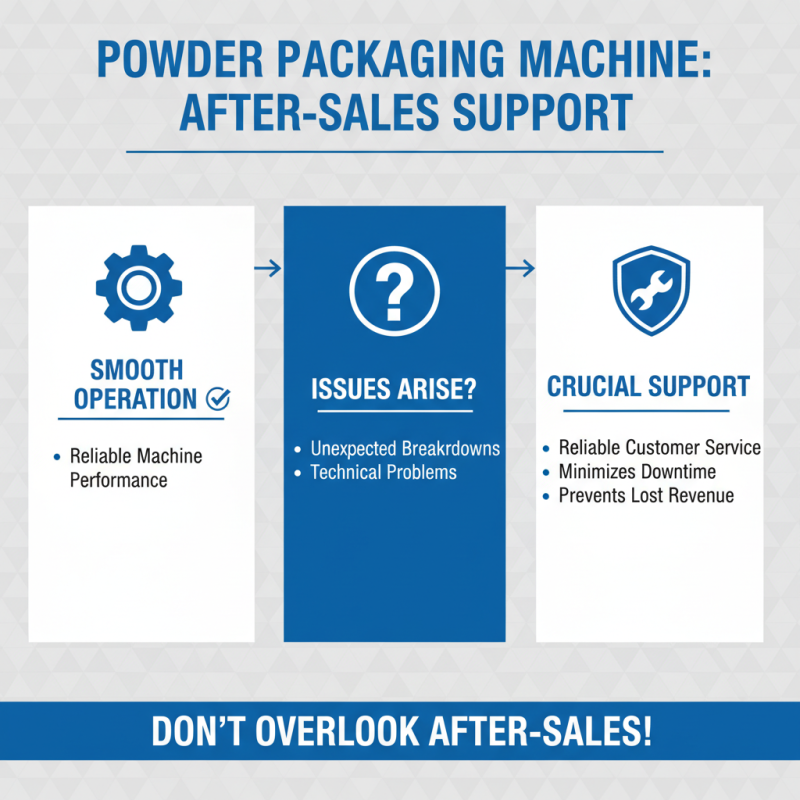

When selecting a powder packaging machine, after-sales support is crucial. You want a machine that operates smoothly. But what happens when issues arise? Does the manufacturer offer reliable customer service? This consideration is often overlooked. A lack of support can lead to downtime and lost revenue.

Maintenance options play a vital role as well. Regular maintenance helps ensure the machine's longevity. Some manufacturers may provide comprehensive service plans. Others might leave you to handle repairs. This distinction is essential in your decision-making process. Think about your capability to address repairs. Are you prepared for the unexpected?

Consider your team's skills too. Inadequate training can lead to operational errors. This can significantly impact productivity. The chosen machine should align with your technical capabilities. Evaluate whether the support team can assist with training. Familiarity with the technology can mitigate issues and enhance efficiency. Thoughtful consideration of after-sales support and maintenance can save you headaches down the road.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals