Choosing the best wire mesh weaving machine is crucial for manufacturers in the industry. In recent years, the wire mesh market has shown significant growth. According to a 2022 industry report, the global wire mesh market is projected to reach $8 billion by 2025. This growth highlights the importance of selecting the right machinery.

Experts emphasize the role of quality in wire mesh production. John Smith, a leading industry expert, states, "Investing in a high-quality wire mesh weaving machine is key to staying competitive." Choosing the right machine can improve production efficiency and product quality. However, many forget to consider the long-term operational costs.

Potential buyers often focus solely on the price tag. This blind spot can lead to higher expenses in maintenance and energy. Understanding specific needs is essential. Features such as versatility, strength, and output rate matter. Ultimately, the choice of a wire mesh weaving machine can shape a company's future in the market. Reflecting on these aspects helps avoid costly mistakes.

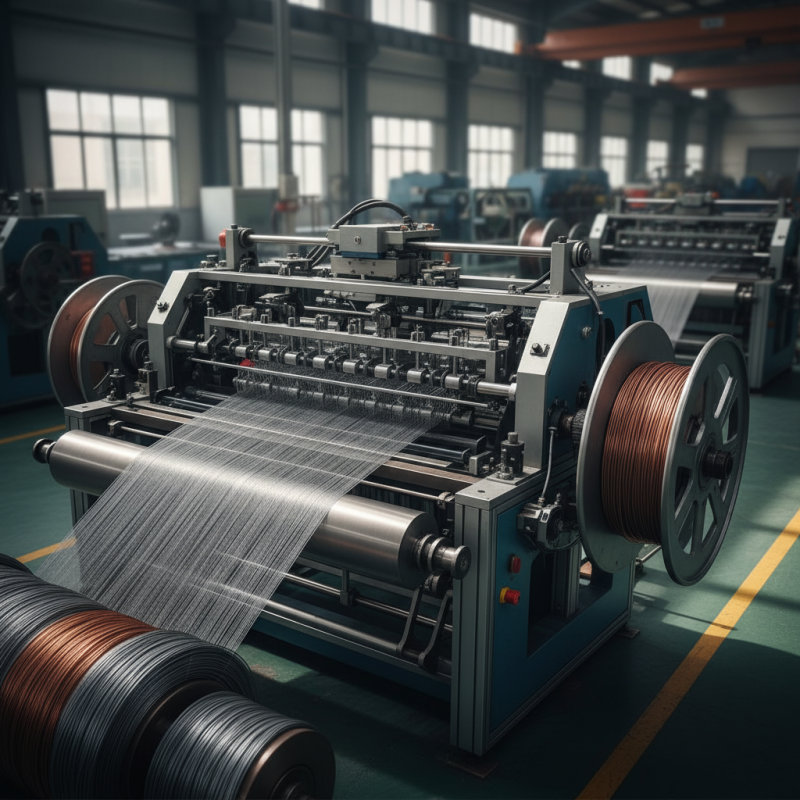

Wire mesh weaving machines play a crucial role in various industries. They create different types of wire meshes used for construction, fencing, and filtration. Understanding the basics of these machines can help in making informed choices.

The weaving process involves feeding wire into the machine, which interlaces it to form mesh patterns. Different machines offer various weaving techniques, like plain weave or twill weave. It's essential to consider the desired mesh specifications. Some machines produce finer mesh, while others are suitable for heavy-duty applications. Depending on production needs, machine speed and efficiency also matter.

Choosing the right machine isn't always straightforward. The initial cost can be high, yet maintenance and operational costs vary significantly. Operators must also be trained to handle the machinery. A poorly understood machine can lead to decreased productivity. This underscores the need for thorough research and understanding before making a purchase. Reflecting on your specific requirements will yield better results in the long run.

Choosing the right wire mesh weaving machine involves several crucial factors. First, consider the machine's capacity. Look into how much material it can handle. Machines vary in speed and output. Make sure the machine aligns with your production needs. A machine that is too slow may hinder your operations. Conversely, a very fast machine might not be cost-effective if you can't keep up with demand.

Next, analyze the types of materials you intend to use. Different machines are designed for various wire thicknesses and types. Test a few machines if possible. You might find that some adjustments are necessary for specific materials. Additionally, consider the ease of maintenance. A complex machine could lead to longer downtimes for repairs. This is not ideal for consistent production schedules.

Lastly, assess the level of automation you require. Fully automated machines can save labor but might be expensive. Manual machines are cheaper, yet they demand more effort. Think about your workforce's skill level. Sometimes, investing in training can be as critical as the machine itself. Balancing these factors is essential for making a savvy choice.

When selecting a wire mesh weaving machine, consider the various types available on the market. These machines can broadly be categorized into automatic and semi-automatic models. Automatic machines are efficient and require minimal human intervention. They are perfect for large-scale production but can be costly. Semi-automatic machines are more flexible and can handle smaller runs. However, they require more manual oversight.

Another important type is the flat wire mesh weaving machine. This machine produces flat, durable meshes suitable for many applications. You might also encounter machines designed for specific wire types, such as stainless steel or copper. These machines are tailored to meet the unique requirements of different industries.

Tip: Always assess your production needs before purchasing a machine. Consider the mesh size and wire thickness you require. Check the machine’s capacity and speed to ensure it matches your production goals. Sometimes, opting for a cheaper model may lead to higher operational costs later, so think carefully.

Ultimately, understanding these types will help you make a better choice. There is no perfect option. Rely on industry reviews and performance metrics but also learn from owners’ experiences. You may find that what works well for one operation may not suit yours.

| Type of Machine | Wire Diameter Range (mm) | Weaving Style | Production Speed (m/min) | Applications |

|---|---|---|---|---|

| Automatic Plain Weaving Machine | 0.5 - 5.0 | Plain Weave | 20 - 30 | Industrial Fencing, Filtering. |

| Jacquard Wire Mesh Weaving Machine | 0.3 - 4.0 | Jacquard Weave | 15 - 25 | Decorative Fabrics, Artwork. |

| Loom Wire Mesh Machine | 0.4 - 3.5 | Loom Weave | 10 - 20 | Screening, Sifting. |

| Wire Mesh Welding Machine | 0.5 - 6.0 | Welded Mesh | 30 - 50 | Construction, Reinforcement. |

| Chain Link Fence Machine | 2.0 - 4.0 | Chain Link | 40 - 60 | Fencing, Security. |

When evaluating the quality and durability of weaving machines, consider the materials used in production. Machines built with high-quality steel tend to withstand wear and tear better. Check for rust resistance and overall sturdiness. It’s essential that the components fit together seamlessly to avoid any malfunction.

Inspection of the weaving patterns produced can also indicate the machine's reliability. Fine, consistent patterns are a sign of a well-made machine. On the contrary, uneven or erratic patterns may suggest issues in the weaving process.

Don’t ignore the importance of user feedback. Reach out to other operators for their experiences. What do they wish they’d known before purchasing? Their insights can help highlight less obvious flaws. A machine may look perfect on the surface but could have underlying issues. Pay attention to details, and test the machine if possible.

When choosing a wire mesh weaving machine, cost and performance are critical factors. Analyzing these two components can feel overwhelming. It's essential to balance quality with your budget. More expensive machines often promise durability and efficiency. However, lower-priced options may suffice for smaller projects.

Consider the specifics of performance. A machine's speed can influence production levels. Faster machines often come with higher price tags. But is that speed necessary for your workload? Reflect on the types of projects you'll handle. Sometimes, slower machines provide better precision, which is crucial for complicated designs.

Cost isn't solely about the initial investment. Maintenance and operational costs add up over time. Machines that seem affordable may require more frequent repairs. This leads to hidden expenses. Assessing long-term costs versus short-term savings is vital. Each decision holds weight. Take the time to evaluate your needs and budget.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals