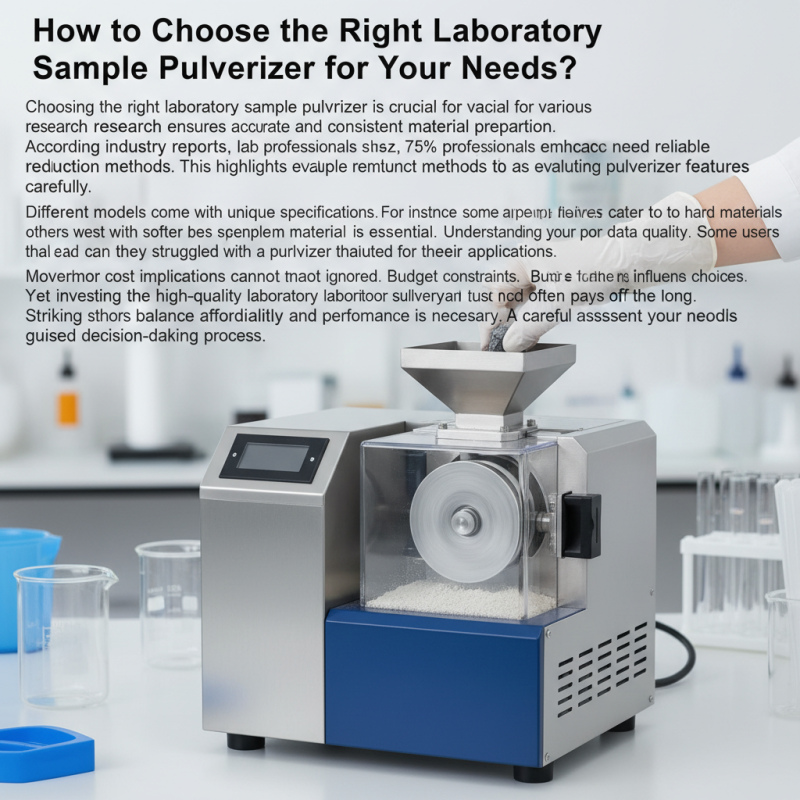

Choosing the right laboratory sample pulverizer is crucial for various research applications. A laboratory sample pulverizer ensures accurate and consistent material preparation. According to industry reports, 75% of lab professionals emphasize the need for reliable sample reduction methods. This highlights the importance of evaluating pulverizer features carefully.

Different models come with unique specifications. For instance, some pulverizers cater to hard materials while others work best with softer ones. Understanding your sample material is essential. A mismatch can lead to poor data quality. Some users report that they struggled with a pulverizer that was not suited for their applications.

Moreover, cost implications cannot be ignored. Budget constraints may influence choices. Yet, investing in a high-quality laboratory sample pulverizer often pays off in the long run. Striking a balance between affordability and performance is necessary. A careful assessment of your needs should guide your decision-making process.

When selecting a laboratory sample pulverizer, understanding the different types is crucial. There are various models, each designed for specific applications. A ball mill, for example, is versatile and can handle tough materials. It's effective for fine grinding but may require longer processing times.

Meanwhile, a hammer mill provides a different approach. It offers high-speed impact for quick pulverization. This method is suitable for soft to medium-hard materials. However, it may not achieve the same level of finesse as a ball mill. Users should evaluate their material types and desired particle sizes before making a decision.

Choosing the right pulverizer can be challenging. Consider factors like material hardness and desired output size. Certain pulverizers can bridge the gap between efficiency and quality but may involve compromises. One must reflect on these aspects to avoid costly mistakes. Being well-informed can significantly enhance your sample preparation process.

Choosing the right laboratory sample pulverizer is crucial. Various factors influence this decision. Material type plays a significant role. Harder materials require sturdier equipment. According to industry studies, a suitable pulverizer can enhance efficiency by over 30%.

Consider the desired particle size. Different applications need specific ranges. Some processes require finer particles, while others are okay with coarser materials. Understanding your requirements here is essential. Also, think about the throughput. A high-capacity pulverizer might be necessary for larger batches. However, it could lead to higher costs.

Cost-effectiveness is another key factor. A cheaper pulverizer might not deliver the desired results, necessitating replacements. Research shows that a quality machine can reduce long-term expenses. User feedback and reviews often highlight these aspects, yet individual experiences may vary. It’s important to analyze both specifications and practical usage. Reflection on your unique needs can guide you to make a better choice.

When selecting a laboratory sample pulverizer, evaluating material compatibility is crucial. Different materials react differently during pulverization. Some may produce heat, while others can be abrasive. This affects the choice of pulverizer for your specific needs. Knowing your materials can save time and improve efficiency.

Tips: Conduct small tests with various settings. This helps identify the best conditions for your materials. Don't skip this step. Understanding how each material behaves under pressure is vital. It can lead to unexpected results if ignored.

Some materials might release fumes or create dust. This can pose safety risks. Ensure the pulverizer you choose can handle these aspects effectively. Consider the strength of your materials. Brittle materials may shatter easily, while tougher types require more powerful equipment.

Tips: Always read technical specifications. Look for features designed to handle your specific materials. It’s okay to feel lost with so many options. Ask questions and seek advice from experts. Ultimately, making informed choices leads to more efficient processes in the lab.

Choosing the right sample pulverizer is vital for laboratory success. The sample size impacts the accuracy of results. Smaller samples can lead to inconsistencies in analyses. However, larger samples may not provide the desired fineness needed for specific applications. Striking a balance between size and fineness is key.

Fineness affects how well a material is prepared for testing. Different applications require unique particle sizes. For example, pharmaceuticals need very fine powders for efficacy. On the other hand, geological samples often need a coarser grind. The goal is to achieve the right particle distribution without compromising sample integrity.

Sometimes, laboratories overlook the importance of sample preparation. They may rush the process, leading to unsatisfactory results. A pulverizer that works well for one application may not suit another. It's crucial to evaluate your specific needs and understand how sample size and fineness relate to your laboratory processes. Regularly reviewing and adjusting your approach can help improve outcomes.

When selecting a laboratory sample pulverizer, cost-effectiveness is key. A high-quality pulverizer may seem expensive upfront. However, lower-quality options can lead to frequent repairs, increasing long-term costs. Consider durability and functionality. Investing in a robust machine often saves money over time.

Tips: Look for a pulverizer that fits your specific needs. Assess your material types and desired outcomes. Think about the volume you handle. Balancing quality and budget can be tricky. It’s easy to overlook maintenance costs. Factor them into your total investment.

Buying a cheaper pulverizer can feel tempting. Yet, it might lack the precision or power required for your tasks. This could hamper your efficiency. Researching specifications thoroughly is essential. Don’t shy away from asking for user reviews. Insights from current users can reveal potential hidden expenses.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals