Choosing the right liquid filling machine is crucial for any business in the packaging industry. According to industry expert John Smith, "Selecting the right equipment can significantly enhance production efficiency." The landscape of liquid filling technology can be overwhelming. Different machines cater to varying needs, capacities, and types of liquids.

When assessing your options, consider the consistency of your product. Thicker liquids may require machines with specialized features. Additionally, think about the scale of your operation. A small business may need a more simplistic model, while larger operations might require advanced automation. It's essential to weigh these variables carefully.

Not all machines fit every scenario. Some may offer flashy features but don’t provide reliable results. For example, a high-speed machine may not suit a thick liquid that clogs easily. Reflect on your company’s needs and production goals. Ensuring a proper fit will save you from potential headaches down the road.

When selecting a liquid filling machine, understanding the various types is crucial. Gravity fillers are often used for free-flowing liquids. They rely on gravity to dispense liquid into containers. This method is simple and cost-effective. However, it may not be suitable for thicker liquids.

Piston fillers offer more precision. They use a piston to measure an exact volume of liquid. This type is ideal for viscous products. But they are usually more complex and expensive than gravity fillers. The consistency and accuracy in filling can be impressive. Still, machine maintenance may be a challenge.

Pump fillers can handle a range of consistencies. They can fill both thin and thick liquids. This versatility makes them a popular choice. However, the choice of pump type can complicate matters. Positive displacement pumps might work for some liquids but not for others. Misaligned parts or improper setup can lead to wasted product. Understanding your production requirements is vital for making the right decision.

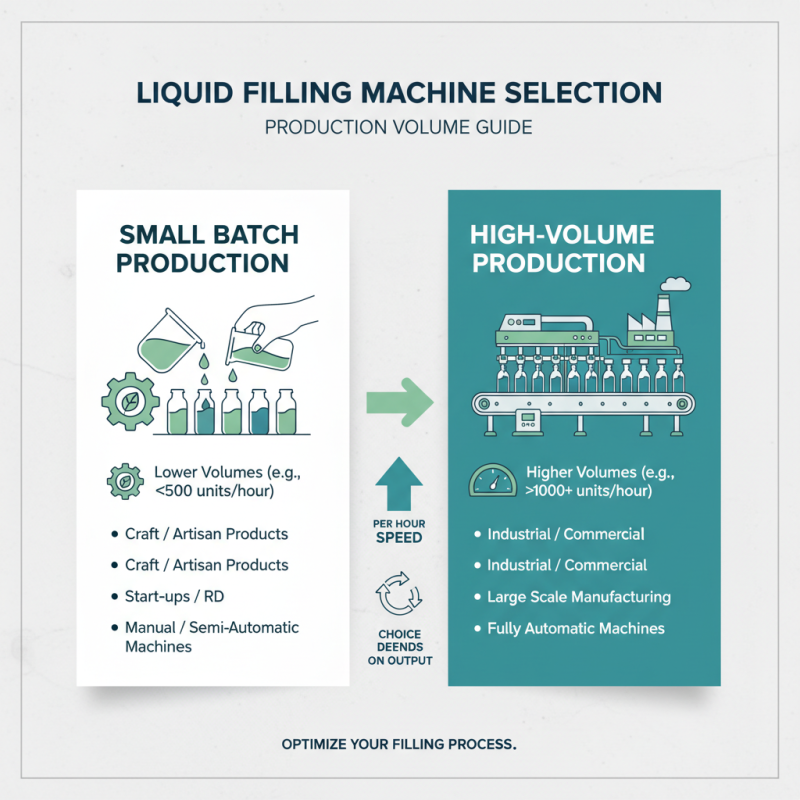

When choosing a liquid filling machine, consider the volume of production. Knowing how much liquid you need to fill per hour helps narrow down the options. Different machines handle various speeds. Some work well for small batches, while others are better for high-volume production.

It's essential to evaluate the types of liquids you will fill. Viscosity and foaming properties affect the choice of technology. For instance, thick liquids require different mechanisms compared to thin ones. A common oversight is underestimating this factor. Always test the machine with a sample of your liquid before purchase.

Tips: Assess the machine's adaptability. Can it handle different bottle sizes? Flexibility is crucial as your needs may change over time. Also, consider the machine’s cleaning and maintenance process. Complicated maintenance may lead to unnecessary downtime.

Lastly, think about your budget. The initial cost is important, but don’t forget operating costs. Sometimes, a cheaper machine incurs higher expenses in the long run. Keep these factors in mind, and make a decision that best aligns with your production goals.

When selecting a liquid filling machine, understanding production volume and speed is crucial. The first step is to know your production needs. Are you filling thousands of bottles or just a few hundred? Large volumes demand faster machines, while low-volume operations can work with slower options. This choice impacts your budget and efficiency.

Speed is another critical factor. Different machines operate at varying speeds. For instance, some can fill up to 100 bottles per minute. This speed is essential for high-demand environments. However, if your products have varying viscosities, this may complicate the process. Slower machines might provide better accuracy for thicker liquids, but at the cost of production speed. Balancing speed with accuracy is not always easy.

Consideration of changeover time is necessary too. If you switch product types frequently, a versatile machine could save you time. Machines that require extensive calibration can delay production. It's essential to think about the future. Will your production volume grow? Choosing a machine that adapts to changing demands can lead to better long-term outcomes. Evaluating these factors carefully can ensure your filling machine meets your operational needs effectively.

When selecting a liquid filling machine, it's essential to consider material compatibility. Different liquids require specific materials to prevent contamination. For instance, acidic substances may react with certain metals, leading to corrosion. Choose materials that can withstand the chemical composition of your liquid. Stainless steel is often recommended for many applications, but not all formulations will tolerate it.

Container types also play a significant role. Bottles, pouches, and drums each have unique filling requirements. A machine designed for plastic pouches may not work efficiently with glass bottles. Evaluate the size and shape of your containers. Ensure the filling machine can accommodate these factors without compromising speed or accuracy.

It’s important to reflect on the long-term viability of your choices, especially if your product line expands. A machine that fills one type of container might limit future growth. Balancing current needs with potential changes can be tricky. Don't hesitate to seek input from manufacturers. Their experience can provide valuable insights, even if you think you have everything figured out.

When considering a liquid filling machine, budgeting is crucial. The initial purchase cost can vary widely. It's essential to assess your specific needs before making a decision. Factors such as production volume and liquid type greatly affect price. A machine for thicker liquids often costs more than those for water-like products.

Maintenance costs should not be overlooked. Regular maintenance ensures efficiency and longevity. Budget for spare parts and any service fees that might arise. A well-maintained machine can save you money in the long run. Neglecting this aspect might lead to costly downtime.

Tips: Research the best maintenance practices for your chosen machine. Soft maintenance agreements might help manage unexpected costs. Consider hiring a professional for initial setup and training. This investment often pays off through smoother operations. If your budget is tight, don’t rush. Take time to evaluate all options carefully.

| Filling Machine Type | Initial Purchase Cost ($) | Annual Maintenance Cost ($) | Filling Speed (BPM) | Best For |

|---|---|---|---|---|

| Gravimetric Filler | 10,000 | 1,200 | 30 | Viscous liquids |

| Pneumatic Filler | 8,000 | 800 | 50 | Liquid and semi-liquid products |

| Volumetric Filler | 7,500 | 600 | 40 | Water, oils, and juices |

| Semi-Automatic Filler | 5,000 | 400 | 20 | Small-scale production |

| Automatic Filler | 15,000 | 1,500 | 100 | High-volume production |

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals