The use of a commercial vacuum packing machine has emerged as a pivotal strategy for enhancing food preservation in various sectors, including restaurants, food manufacturing, and home kitchens. According to a recent report by MarketsandMarkets, the global vacuum packaging market is projected to reach USD 32.79 billion by 2027, growing at a CAGR of 4.7% from 2020 to 2027. This growth is driven by the increasing consumer demand for extended shelf life and improved food safety. By effectively removing air and sealing products in an airtight environment, a commercial vacuum packing machine significantly reduces the risk of spoilage, bacterial growth, and freezer burn.

Additionally, a study published in the Journal of Food Science has shown that vacuum-sealed foods can maintain their nutritional quality for up to five times longer than conventionally packaged items. As the food industry increasingly adopts these technologies, the need for efficient and reliable preservation methods has never been more critical.

Additionally, a study published in the Journal of Food Science has shown that vacuum-sealed foods can maintain their nutritional quality for up to five times longer than conventionally packaged items. As the food industry increasingly adopts these technologies, the need for efficient and reliable preservation methods has never been more critical.

Commercial vacuum packing machines offer various benefits that significantly enhance food preservation. First and foremost, these machines effectively remove air from packaging, which helps to extend the shelf life of perishable items. By minimizing the presence of oxygen, vacuum sealing inhibits microbial growth and oxidation, keeping food fresher for longer. This is particularly useful for restaurants and food services where maintaining high-quality ingredients is crucial to ensuring customer satisfaction.

Tips for choosing the right vacuum packing machine include considering the size of your operation and the types of foods you package. For smaller businesses, a countertop model may suffice, while larger establishments opting for high-volume production should choose industrial-grade machines. Additionally, look for machines that offer adjustable settings for different food types—this versatility ensures optimal sealing for delicate items like bread or more robust products like meats.

Another advantage of using commercial vacuum packing machines is the ability to reduce food waste. By preserving surplus ingredients efficiently, businesses can minimize losses and improve their bottom line. Implementing vacuum sealing as part of your inventory management can lead to significant savings while promoting sustainability in food practices.

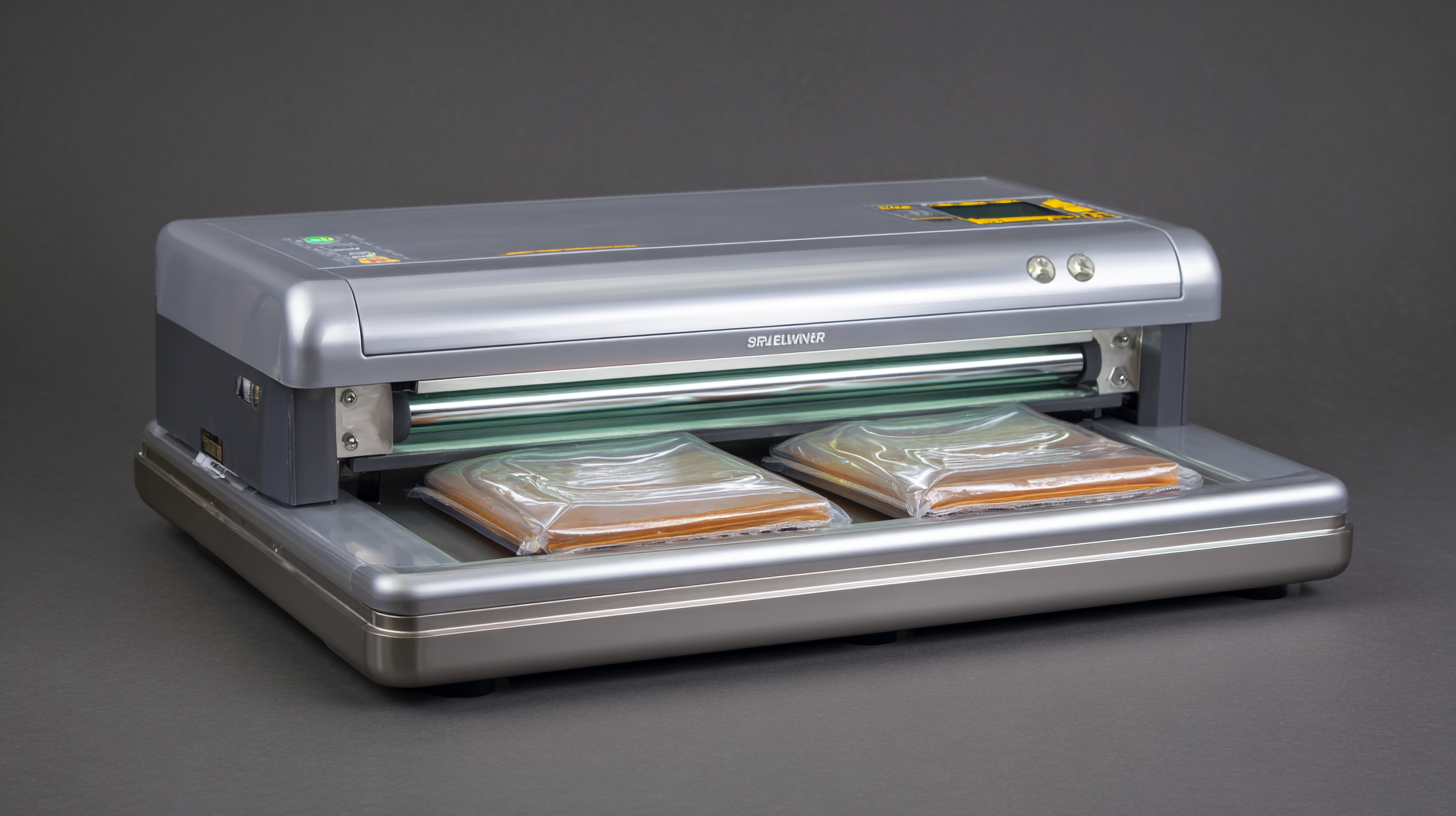

When selecting a high-quality commercial vacuum packing machine, there are several key features to consider that can significantly enhance your food preservation efforts. First and foremost, look for machines that offer strong suction power, as this is essential for removing air efficiently and ensuring that food stays fresh for longer periods. Additionally, a machine with adjustable sealing time settings allows for customization based on the type of food being packaged, which can further improve the effectiveness of the sealing process.

Another important feature is the presence of a built-in cutter or roll storage, which facilitates the creation of custom-sized bags tailored to your food items. This versatility not only saves time but also reduces waste. Furthermore, consider models that include advanced technology, such as moisture and soft air sensors, to protect delicate items like fruits and vegetables during the sealing process. With these essential features, a high-quality vacuum packing machine can significantly boost the longevity and quality of your stored food.

Vacuum packing has become a leading method in food preservation, significantly outperforming traditional techniques. According to a 2022 industry report from the Food Preservation Association, vacuum-sealed products can extend shelf life by 3-5 times compared to conventional methods such as canning or freezing. This is particularly crucial for commercial operations, where maintaining product quality and safety is paramount. Traditional methods often rely on exposing food to air, which accelerates oxidation and spoilage, while vacuum packing removes air, effectively stalling these processes.

In a comparative analysis, studies have shown that vacuum packing not only retains the taste and nutritional value of food but also minimizes the risk of foodborne illnesses. The National Institute of Food Safety reported that vacuum-sealed products exhibited a 75% reduction in spoilage and contamination rates, making them safer for longer storage periods. Additionally, this method results in less waste, meeting the growing consumer demand for sustainability in food storage. As technology in vacuum packing machines continues to advance, the advantages over traditional preservation methods are becoming increasingly clear for both businesses and households alike.

Vacuum packing has emerged as a powerful tool in the battle against food waste. Industry statistics reveal that approximately 30% of the food produced globally is wasted, generating significant economic and environmental costs. By utilizing commercial vacuum packing machines, food businesses can actively contribute to reducing this statistic. Studies show that vacuum sealing can extend the shelf life of food products by up to five times compared to traditional packaging methods, effectively minimizing spoilage and fostering sustainability.

Moreover, vacuum packing not only preserves food quality but also reduces the volume of waste generated by bulky packaging. This method not only keeps food fresher for longer periods but also helps in better inventory management, allowing businesses to plan more efficiently and reduce overproduction. As the food industry continues to embrace advanced preservation techniques, the adoption of commercial vacuum packing is becoming essential for reducing food waste, ultimately leading to a more sustainable and responsible food supply chain.

| Year | Food Waste Reduction (%) | Average Shelf Life Increase (days) | Commercial Vacuum Packing Machines Sold | Total Industry Revenue ($ Million) |

|---|---|---|---|---|

| 2018 | 15% | 5 | 120,000 | 450 |

| 2019 | 20% | 7 | 150,000 | 550 |

| 2020 | 25% | 10 | 200,000 | 600 |

| 2021 | 30% | 12 | 250,000 | 700 |

| 2022 | 35% | 15 | 300,000 | 800 |

Vacuum packing is an effective method for preserving food while extending its shelf life. By removing air from the packaging, vacuum sealing prevents the growth of bacteria and mold, thereby maintaining the freshness and flavor of various food products. To maximize the benefits of vacuum packing, it’s crucial to understand the best practices tailored to specific types of food. For instance, when packaging soft items like fruits and cheeses, using a gentle vacuum setting can help retain their shape and texture.

Additionally, different materials play a significant role in the effectiveness of vacuum packaging. Polyethylene and polypropylene are commonly used due to their excellent sealing properties and resistance to moisture. For high-fat items, polyamide may be a better option because of its barrier properties against oxygen, which helps in preventing rancidity. Understanding these materials and their application can enhance food preservation significantly while ensuring that the quality and safety of the food are maintained over time.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals