In the ever-evolving landscape of food packaging, adhering to stringent import and export certifications is essential for manufacturers seeking to deliver excellence. A study by the Food and Agriculture Organization (FAO) highlights that improper sealing can lead to approximately 25% of food waste, underscoring the critical role of the sealing machine for food packaging in preserving product integrity and safety.

As global trade in food products grows, with the International Trade Centre reporting a steady increase in food exports reaching over $1.5 trillion annually, the demand for reliable, compliant sealing technologies has never been more significant. Navigating through the myriad of industry production standards and understanding the certification process becomes paramount for businesses aiming to enhance their operational efficacy and market access.

This blog will explore the essential aspects of certification for sealing machines, equipping manufacturers with the knowledge required to meet regulatory requirements and succeed in the competitive food packaging sector.

As global trade in food products grows, with the International Trade Centre reporting a steady increase in food exports reaching over $1.5 trillion annually, the demand for reliable, compliant sealing technologies has never been more significant. Navigating through the myriad of industry production standards and understanding the certification process becomes paramount for businesses aiming to enhance their operational efficacy and market access.

This blog will explore the essential aspects of certification for sealing machines, equipping manufacturers with the knowledge required to meet regulatory requirements and succeed in the competitive food packaging sector.

In the food packaging industry, understanding import and export certifications is crucial for ensuring compliance with international regulations and standards. These certifications not only facilitate the seamless movement of goods across borders but also guarantee the safety and quality of packaged food products. For businesses investing in sealing machines, these certifications can determine their eligibility to enter various markets, affecting overall profitability and growth opportunities.

Import and export certifications serve as a validation of a product's adherence to safety standards, which is particularly important in the food sector. These certifications reassure consumers and regulatory bodies that the packaging technology used meets established safety and hygiene protocols. Furthermore, possessing the appropriate certifications can enhance a company's reputation and foster trust with stakeholders, which is essential in the competitive landscape of food packaging. By prioritizing certification awareness, businesses can navigate the complexities of international trade more effectively, ensuring that they remain compliant while maximizing their market potential.

When selecting sealing machines for food packaging, understanding the necessary certifications is essential to ensuring product safety and compliance. Key certifications include the FDA approval, which signifies that the materials used in the machine meet safety standards for food contact. Additionally, the European Union's CE marking confirms that the equipment complies with health, safety, and environmental protection standards required in the European market. These certifications not only enhance the credibility of the machine but also help manufacturers avoid legal repercussions and enhance consumer trust.

In addition to FDA and CE certifications, food packaging machinery may also require ISO certification, particularly ISO 22000, which outlines the requirements for food safety management systems. This certification indicates that the manufacturer adheres to international standards for food safety, further assuring customers of the reliability of their sealing equipment. Understanding these key certifications is crucial for businesses to navigate the complex landscape of food packaging machinery and to select the best sealing machine that aligns with legal requirements and industry best practices.

This bar chart illustrates the number of key certifications acquired within the food packaging machinery industry. Each certification is crucial for ensuring compliance with international safety and quality standards, which is vital for import and export operations in food packaging.

When it comes to choosing sealing machines for the food industry, understanding the legal requirements is paramount. Food safety regulations, such as those enforced by the FDA in the United States, mandate specific certifications and compliance standards that sealing machines must meet. These regulations not only ensure the safety and quality of packaged food products but also protect consumers from potential health risks.

Navigating through these legal requirements involves thorough research and often consultation with regulatory bodies. Businesses must ensure that the sealing machines they procure are compliant with local, national, and international standards. This includes evaluating the machine's materials, construction, and operation to confirm they meet hygiene and safety specifications. Additionally, it's essential for manufacturers and distributors to maintain proper documentation and certifications, which serve as proof of compliance during inspections or audits.

Staying informed about evolving regulations and industry standards is crucial for any business in food packaging. By understanding these legal frameworks, companies can not only safeguard their operations but also enhance their product credibility in a competitive market. Investing in certified sealing machines ultimately contributes to the success and sustainability of food packaging practices.

Staying informed about evolving regulations and industry standards is crucial for any business in food packaging. By understanding these legal frameworks, companies can not only safeguard their operations but also enhance their product credibility in a competitive market. Investing in certified sealing machines ultimately contributes to the success and sustainability of food packaging practices.

When selecting a certified sealing machine for your food packaging needs, it is essential to prioritize compliance with industry standards and certifications. The food packaging sector is governed by regulations such as the FDA and ISO standards, which ensure the machinery meets safety and efficiency benchmarks.

For example, a study published by the Food Packaging Forum indicated that using certified sealing machines can reduce contamination risks by up to 30%, thereby enhancing food safety. This underlines the importance of choosing equipment that is compliant with applicable regulations.

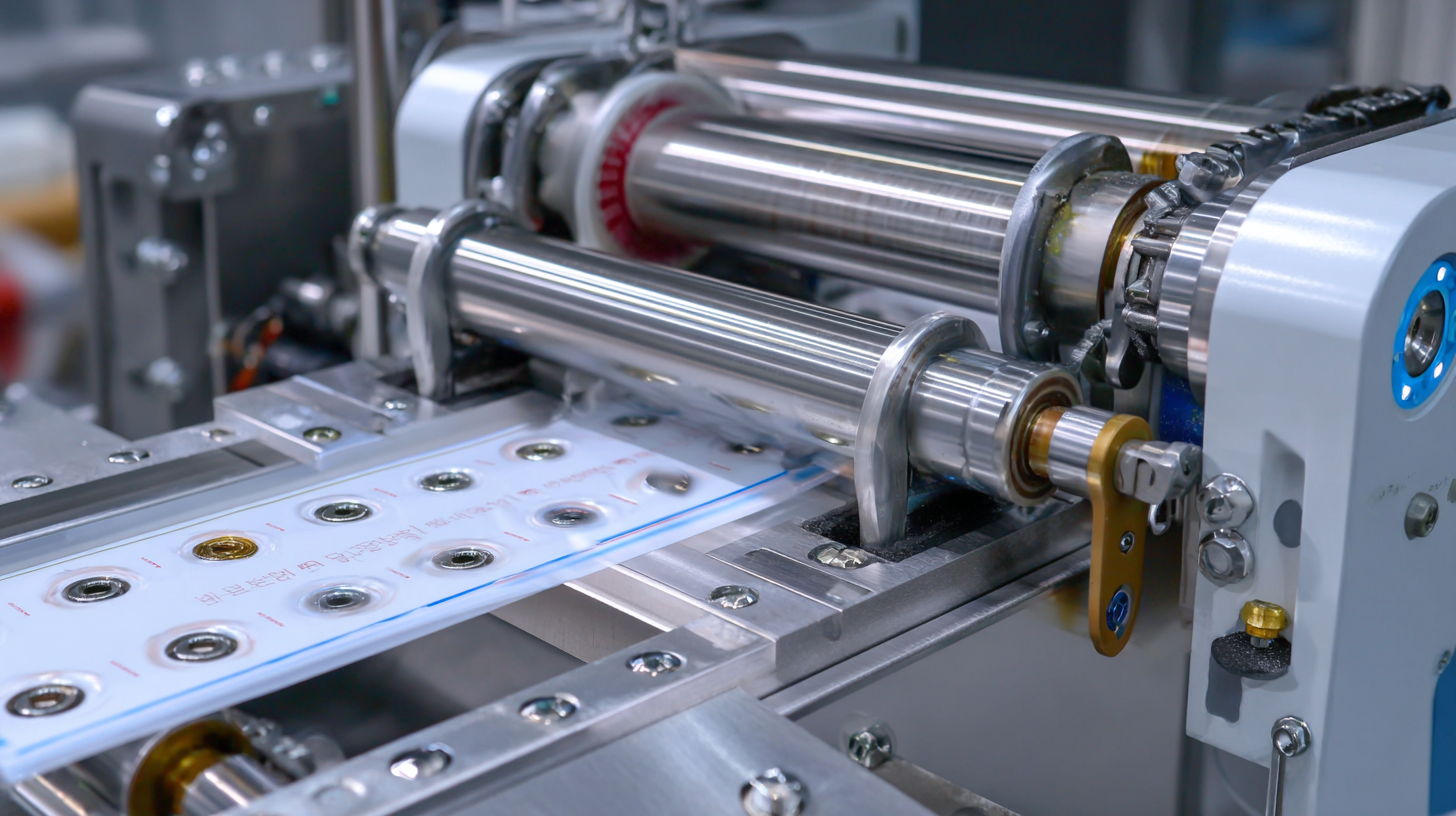

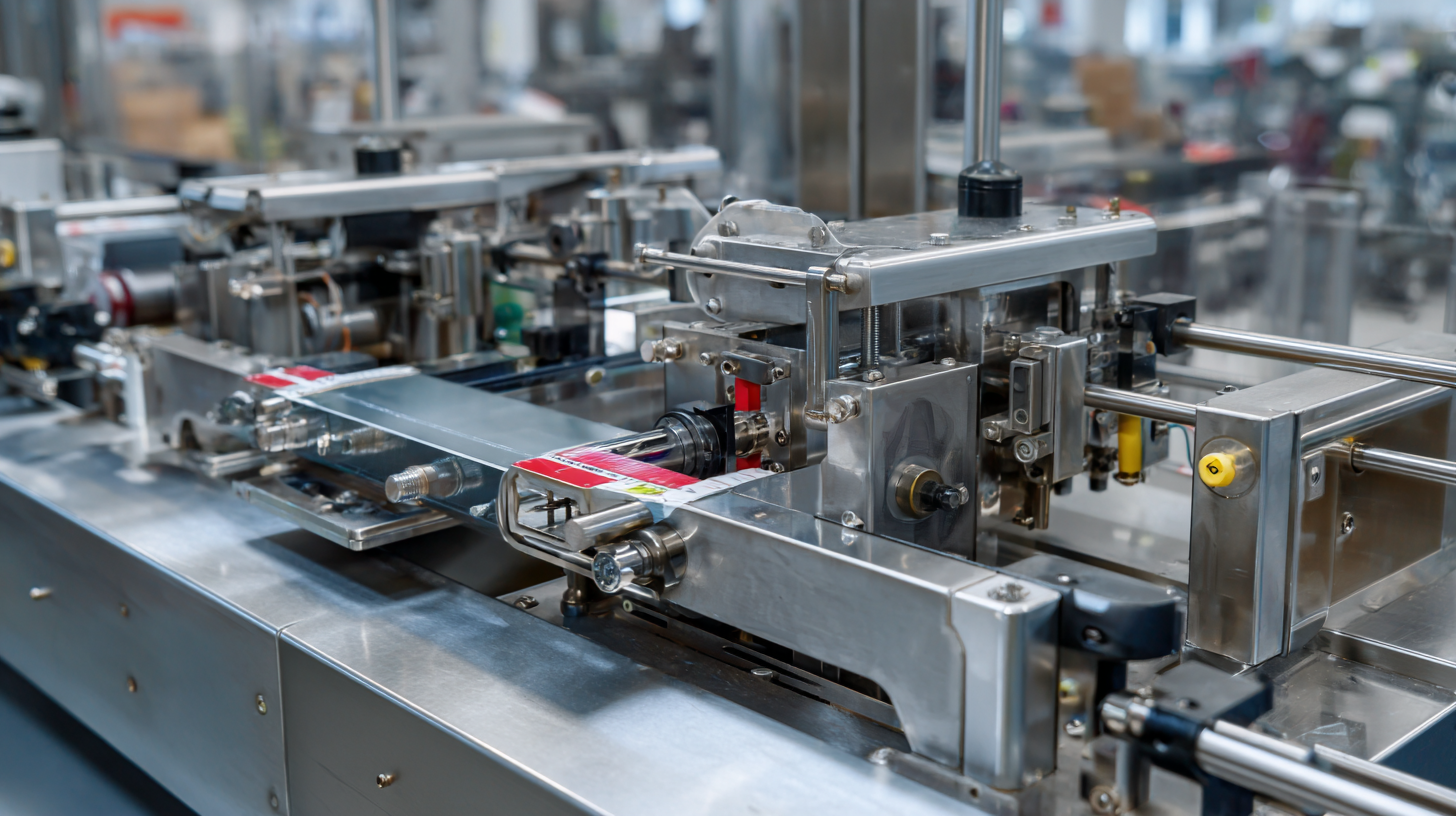

Additionally, consider the technical specifications of the sealing machines. A report by MarketsandMarkets highlights that the global food packaging equipment market is expected to grow from USD 33.33 billion in 2020 to USD 45.65 billion by 2025, driven by the demand for high-quality sealing machines.

Features such as adjustable temperature controls, speed, and compatibility with various materials are crucial for optimizing production efficiency. Investing in a certified machine with proven reliability can lead to significant cost savings and increased product longevity, ultimately benefiting your bottom line in the competitive food industry.

In today's rapidly evolving food packaging industry, maintaining compliance with import and export certifications is paramount. Recent initiatives, such as the FDA's ongoing efforts to improve food labeling practices, highlight the increasing scrutiny on food packaging operations. For instance, the adoption of standardized "Best if Used By" and "Use By" dates, as seen in California's recent legislation, serves to minimize consumer confusion and enhance safety. This legislative change underscores the importance of having clear labeling that aligns with regulatory requirements.

Moreover, leveraging automation technologies can significantly bolster compliance in food packaging operations. These innovations not only streamline sanitation and quality control processes but also mitigate risks associated with the use of harmful substances. With growing concerns over per- and polyfluoroalkyl substances (PFAS) in food packaging, regulatory constraints are tightening. As organizations navigate these complexities, adopting a Food Safety Management System (FSMS) and implementing Hazard Analysis Critical Control Points (HACCP) principles can provide structured approaches to minimize risks and ensure adherence to food safety regulations. Such proactive measures are essential for businesses aiming to thrive in a competitive and regulated market.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals