In recent years, the demand for small scale bottle filling machines has experienced significant growth, driven by the rise of artisanal and small-batch production across various industries. According to a report by Smithers, the global filling equipment market is projected to reach approximately $5.8 billion by 2026, with small scale solutions gaining traction due to their versatility and affordability. This segment has become increasingly popular among startups and small businesses looking to streamline their operations and enhance product quality without the overhead costs associated with larger systems.

Small scale bottle filling machines cater to a diverse range of sectors, including food and beverage, cosmetics, and specialty chemicals. Their compact design and flexibility allow businesses to adapt quickly to changing market demands and consumer preferences. Research from MarketsandMarkets indicates that the small scale packaging market is expected to grow at a CAGR of 7.2% from 2021 to 2026, reinforcing the crucial role that efficient filling solutions play in meeting industry needs. As we move into 2025, understanding the options available in this dynamic market is essential for buyers aiming to optimize their production processes while maintaining high-quality standards.

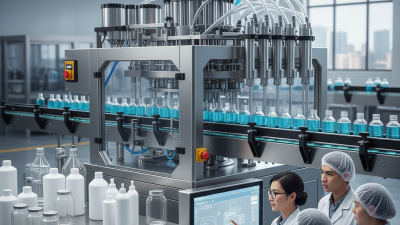

As the demand for small scale production continues to rise, small scale bottle filling machines have become essential tools for many businesses in 2025. These machines are specifically designed to cater to smaller production runs, making them ideal for startups, craft beverage manufacturers, and artisanal producers. With advancements in technology, modern filling machines offer enhanced efficiency and accuracy, ensuring minimal waste and optimal use of resources.

In 2025, the market for small scale bottle filling machines features a variety of options that accommodate different bottle sizes, materials, and filling techniques. Key considerations for buyers include the machine's compatibility with diverse products, ease of use, and maintenance requirements. Many machines now come equipped with automated systems that streamline the filling process, reducing labor costs and increasing output. Furthermore, innovations such as adjustable filling speeds, quick-change parts, and user-friendly interfaces are making these machines more accessible for businesses aiming to scale up without substantial investment.

When selecting a small scale bottle filling machine, understanding the key features that can significantly enhance efficiency and productivity is crucial. According to a recent industry report by Grand View Research, the global bottle filling equipment market is projected to reach $5.5 billion by 2025, highlighting the increasing demand for advanced filling technologies. One of the primary features to look for is the machine's speed and output capacity. Machines capable of filling 30 to 60 bottles per minute are ideal for small-scale operations, allowing businesses to maintain a steady workflow without compromising quality.

Another essential aspect is the versatility of the machine. The ability to accommodate various bottle sizes and types — from glass to plastic — is vital for businesses that aim to diversify their product offerings. Recent surveys indicate that over 70% of small to medium enterprises benefit from machines that allow quick changeovers to different bottle specifications without extensive downtime. Additionally, the ease of cleaning and maintenance should not be overlooked; equipment that is designed with user-friendly features can help reduce operational costs and improve production efficiency in the long term.

The bottle filling industry is undergoing significant transformations, driven by advancements in technology and changing consumer preferences. As we look towards 2025, automation and efficiency are set to redefine the landscape. Small scale bottle filling machines are becoming increasingly sophisticated, enabling small businesses to enhance productivity while maintaining quality. With a growing emphasis on sustainability, manufacturers are also focusing on eco-friendly packaging solutions, aligning with the global push for reduced environmental impact.

Market trends indicate a rising demand for customizable filling solutions as businesses cater to niche markets and specialty products. The growth of e-commerce and the popularity of artisanal beverages have further fueled the need for versatile and compact filling machines that can adapt to varying bottle sizes and capacities. Projections for the industry signal a bright future, with innovations enhancing ease of use, reducing production costs, and improving filling accuracy, thereby creating more opportunities for small-scale producers in an increasingly competitive market.

As the demand for bottled products continues to rise, small scale bottle filling machines are becoming increasingly essential for businesses looking to enhance production efficiency. According to a recent industry report, the global market for bottle filling machines is projected to grow at a CAGR of 6.7%, reaching approximately $3.8 billion by 2025. This growth is driven by the expanding beverage sector, particularly in craft breweries and artisanal producers who require scalable solutions without compromising on quality.

When exploring the top brands for small scale bottle filling machines, several key features emerge as pivotal in decision-making. Leading manufacturers offer a range of filling technologies, including gravity, vacuum, and pressure filling, each suitable for different types of liquids. For instance, pressure fillers are ideal for carbonated beverages, whereas gravity fillers excel in handling thin, non-viscous liquids. Furthermore, the integration of advanced automation and user-friendly interfaces contributes to increased operational efficiency. Recent surveys indicate that nearly 72% of small businesses prioritize ease of use and machine versatility when selecting filling equipment.

In addition to technology, the choice of materials and design can significantly influence the machine's longevity and maintenance requirements. Machines constructed from stainless steel and featuring modular designs facilitate easier cleaning and sanitation, which is especially important in the food and beverage industry. With sustainability becoming a central focus, brands that incorporate energy-efficient components and lower waste operations are also gaining traction among environmentally-conscious buyers. This landscape showcases an array of options that cater to diverse operational needs while enhancing productivity and sustainability in the small scale bottling market.

| Model | Filling Speed (Bottles per Minute) | Bottle Size Range (ml) | Power Requirement (kW) | Weight (kg) | Dimensions (LxWxH mm) |

|---|---|---|---|---|---|

| Filling Model A | 20 | 100 - 500 | 1.5 | 150 | 800 x 600 x 1500 |

| Filling Model B | 30 | 200 - 1000 | 2.0 | 200 | 900 x 700 x 1600 |

| Filling Model C | 15 | 150 - 750 | 1.2 | 120 | 700 x 500 x 1400 |

| Filling Model D | 25 | 100 - 500 | 1.8 | 175 | 850 x 650 x 1550 |

Maintaining efficiency in bottle filling operations is crucial for small-scale manufacturers aiming to maximize productivity while minimizing downtime. Regular maintenance of filling machines can greatly enhance their longevity and performance. Operators should implement a routine maintenance schedule that includes thorough cleaning of machine components, inspection of seals and gaskets, and timely lubrication of moving parts. This proactive approach prevents potential malfunctions and ensures consistent filling accuracy, which is essential for product quality.

In addition to regular maintenance, optimizing workflow can significantly boost overall efficiency. Practicing good inventory management helps maintain an appropriate supply of bottles and caps, reducing delays during production. Training staff on the operation of filling machines can also contribute to smoother operations. A well-informed team is more adept at troubleshooting minor issues before they escalate, ensuring that the filling process remains uninterrupted. Furthermore, employing automated systems can facilitate faster production rates and reduce human error, making the entire operation more efficient.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals