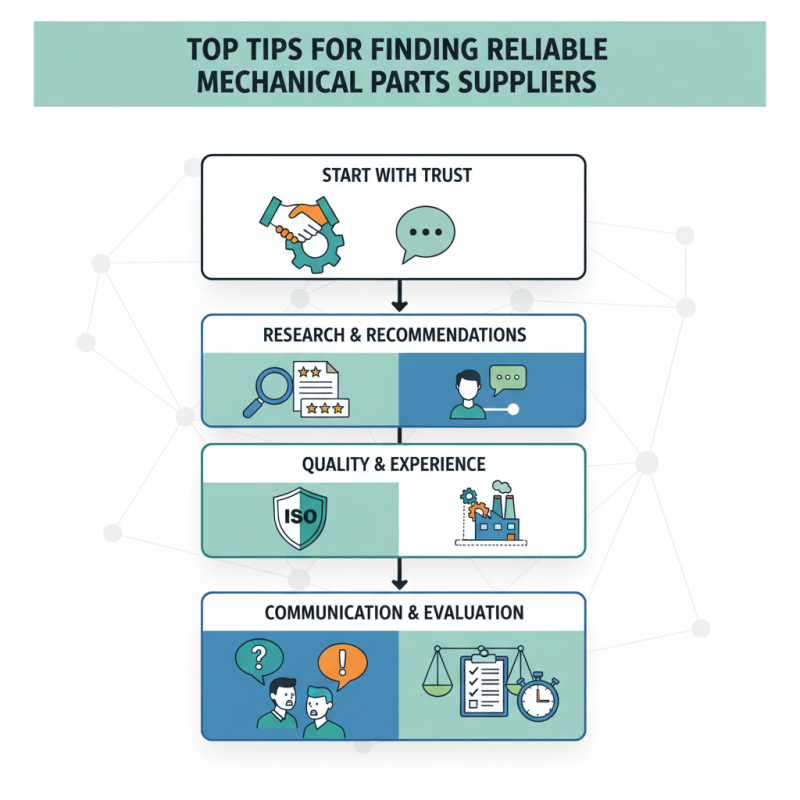

Finding reliable mechanical parts suppliers is crucial for any manufacturing business. As underscored by John Smith, a leading expert in mechanical engineering, “Quality components start with a trustworthy supplier.” Businesses often struggle to identify suppliers who meet their quality standards.

Navigating the marketplace can be overwhelming. Numerous suppliers claim expertise, yet not all deliver reliable products. It is vital to do thorough research. Comparing reviews and seeking recommendations can save time and resources.

When partnering with mechanical parts suppliers, pay attention to their certification and industry experience. A supplier's reputation often reflects their commitment to quality. Engaging in open communication with potential suppliers can reveal their reliability. Don't rush the decision; take time to evaluate your options thoughtfully.

When seeking reliable mechanical parts suppliers, understanding your specific needs is vital. Begin by assessing the type of mechanical components you require. Whether it’s bearings, gears, or fasteners, each component plays a crucial role in your projects. According to a recent industry report, nearly 40% of procurement delays stem from unclear specifications. Clear definitions can steer suppliers toward delivering exactly what you need.

Evaluate the materials and standards necessary for your products. Are you working with high temperatures or corrosive environments? Materials must withstand specific conditions. Research indicates that substandard materials can result in a 25% increase in operational costs due to failures. It’s important to communicate these parameters effectively to potential suppliers. Inadequate discussions can lead to unexpected issues down the line.

Furthermore, consider the quantity and frequency of your orders. Larger orders might negotiate better pricing, but irregular needs can complicate relationships. Suppliers may not prioritize smaller orders, leading to delays. Poor communication here often results in unmet deadlines. Reflecting on your requirements can guide you in selecting the most suitable supplier for your mechanical parts.

Finding reliable mechanical parts suppliers can be a challenging task. Start by researching potential suppliers through industry directories and trade shows. The Manufacturing Industry Institute reports that 70% of businesses rely on close-knit networks for referrals. These networks can lead you to trustworthy contacts.

When assessing suppliers, consider their quality control processes. A study by the American Society for Quality indicates that companies with strict quality measures can reduce defects by 20%. Look for certifications that show compliance with industry standards. They can reflect a supplier's commitment to quality.

Tips: Always request samples before making bulk orders. This helps verify product quality. Check reviews and testimonials online. This feedback can provide insight into a supplier’s reliability. Set up meetings or calls to discuss your specific needs. Personal engagement can reveal a supplier’s dedication to service. Remember, not every supplier will meet your expectations. It’s okay to pivot if something feels off.

When searching for reliable mechanical parts suppliers, assessing their reliability is crucial. Start with their experience in the industry. A supplier that has been around for a while often understands market dynamics better. Look for feedback from their previous customers. Reviews can reveal strengths and weaknesses that influence your decision.

Tip: Request references from potential suppliers. Talking directly with their past clients can provide insights. You might discover overlooked issues, which is key for avoiding future problems. Transparency in communication is essential. If a supplier hesitates to provide information, that could be a red flag.

Another vital aspect is quality assurance. Suppliers should have clear quality control processes. Ask about their certifications. These documents help determine if they meet industry standards. It’s a good sign if they conduct regular audits.

Tip: Visit the supplier’s facility if possible. A site visit can uncover details you might miss in online communication. Engaging directly can lead to a better understanding of their operations and capabilities. Look for inconsistencies in their claims, prompting further questions. Being diligent in your evaluation can make all the difference in supplier reliability.

When searching for mechanical parts suppliers, reviews and references play a vital role. Potential suppliers often present glowing testimonials on their websites. However, it's essential to dig deeper. Look for independent reviews on third-party platforms. They offer a more balanced view. Pay attention to both positive and negative feedback to get a complete picture.

Checking references is another critical step. Contact previous customers to understand their experiences. Did they receive the parts on time? Was the quality satisfactory? Ask about customer service. Direct communications reveal much more than online reviews. These conversations can highlight hidden issues or exceptional service. You may discover a supplier who seems perfect at first glance but has red flags upon deeper investigation. Make sure to ask specific questions to gather all necessary information.

Effective communication is crucial when engaging with potential mechanical parts suppliers. Start by clearly defining your needs. Provide details about the parts, including specifications, dimensions, and expected usage. This sets a foundation for transparent discussions. Ask questions early on. Inquire about lead times, quality control measures, and any previous experience they have with similar products. This will help you gauge their reliability and expertise.

Build a rapport with suppliers. Regular check-ins can strengthen relationships. Use informal communication channels like instant messaging or quick calls for urgent matters. However, do not overlook the importance of written agreements. Documenting key points ensures accountability. Be mindful of cultural differences that may affect communication style. Not every supplier communicates in the same way.

Reflect on any challenges you face during this process. If you find responses slow or unclear, consider adjusting your approach. Analyze if your expectations are realistic or if you need to improve how you present your needs. Strive for clear communication while remaining open to feedback. This way, you can enhance your supplier relationships and improve your procurement process.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals